Basic Principles of Measurement

It’s an argument can be made for asserting that quality begins with measurement. Only when quality is quantified can meaningful discussion about improvement begin. Conceptually, measurement is quite simple: measurement is the assignment of numbers to observed phenomena according to certain rules. Measurement is a sine qua non of any science, including management science.

What is MSA (Measurement System Analysis)

“If you can measure what you are talking about and you can express it with the numbers, then I believe that you have knowledge about the topic!” Lord Kelvin

Measurement System Analysis uses specifically designed experiments to identify components of variation in a measurement system. The resulting data are analyzed to ensure the integrity of data produced by the measurement system. We also analyze the data to understand the impact of measurement error on decision making with that data

If a measurement system cannot be made capable it may be necessary to establish temporary data collection by another method to move the project forward

So MSA is a study that analyzes the impact of:

- Operations

- Procedures

- Personnel (appraisers)

- Equipment and instrumentation

Each component affects the assignment of a value to a measurement characteristic

MSA is not just calibration and is not just Gage Repeatability and Reproducibility (R&R)

When shall we use MSA?

Before you…

- Make decision with data

- Implement solutions

- Run an experiment

- Perform a complex statistical analysis

You should…

- Validate your measurement systems

- Validate data and data collection systems

Bad Data = Bad Decision

Poor measurement systems can be costly by Rejecting satisfactory outputs or accepting unsatisfactory outputs or causing a capable process to appear to have poor capability or even Creating unnecessary expense of trying to fix a process where the primary source of variability is from the measurement system

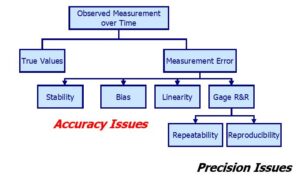

Components of Variation

Fundamentally, any item measure should meet two tests:

- The item measures what it is intended to measure (i.e., it is valid).

- Are measurement would order individual responses in the same way (i.e., it is reliable).

A good measurement system possesses certain properties. First, it should produce a number that is ‘‘close’’ to the actual property being measured, i.e., it should be accurate. Second, if the measurement system is applied repeatedly to the same object, the measurements produced should be close to one another, i.e., it should be repeatable. Third, the measurement system should be able to produce accurate and consistent results over the entire range of concern, i.e., it should be linear. Fourth, the measurement system should produce the same results when used by any properly trained individual, i.e., the results should be reproducible. Finally, when applied to the same items the measurement system should produce the same results in the future as it did in the past, i.e., it should be stable.

Below the components of the Measurement variation

- Stability: Stability is the total variation in the measurements obtained with a measurement system on the same master or parts when measuring a single characteristic over an extended time period. A system is said to be stable if the results are the same at different points in time

- Bias: The difference between the average measured value and a reference value is referred to as bias. The reference value is an agreed-upon standard, such as a standard traceable to a national standards body

- Linearity: the difference in the bias values through the expected operating range of the gage

- Gage R&R – Repeatability and Reproducibility –>

- Repeatability is the variation in measurements obtained with one measurement instrument when used several times by one appraiser, while measuring the identical characteristic on the same part.

- Reproducibility is the variation in the average of the measurements made by different appraisers using the same measuring instrument when measuring the identical characteristic on the same part

- Discrimination

- Accuracy

- Precision

All these components are covered in details in the green belt training and theblack belt training that we deliver.

Measurement system problems fall into two categories

- Location (accuracy) – stability, bias and linearity

- Spread (precision) – repeatability and reproducibility , Precision issues are diagnosed with Gage R&R studies

Let’s see together what are the guidelines of Gage R&R

Gage R&R Study Guidelines

- Verify maintenance and condition of the instrument, repair as needed

- Procure suitable reference standards covering this range and calibrate the instrument

- Document the operating procedure for the instrument

- Choose appraisers who normally perform the testing and ensure they are trained according to the procedure

- Select the number of samples to be tested. At least 5 should be used

- Samples should be labeled for identification such that they will be blind to the appraisers

- Randomize the samples for each appraiser

- Be present and observe the testing

If you are working with attribute data, you can run Attribute Gage R&R

Running an Attribute Gage R&R

- Select between 20 to 30 test samples that represent the full range of variation encountered in the actual process

- Have a master appraiser categorize each sample into its true attribute category

- Select 2 or 3 appraisers who typically perform this classification

- Have them categorize each sample without knowing how the master appraiser has rated them

- Have the appraisers repeat their assessments

- Enter data into Minitab for analysis

If you need to know more and practice some exercises on the MSA, enroll for one of our Green Belt Courses or Black Belt courses

Related Articles

Lean Six Sigma Stories

Read MoreTo improve the usability of our website we use cookies.

More Information Close